Objective: This system is for Packaging of items from the production area and acknowledge that item has reached to the dispatch area or not.

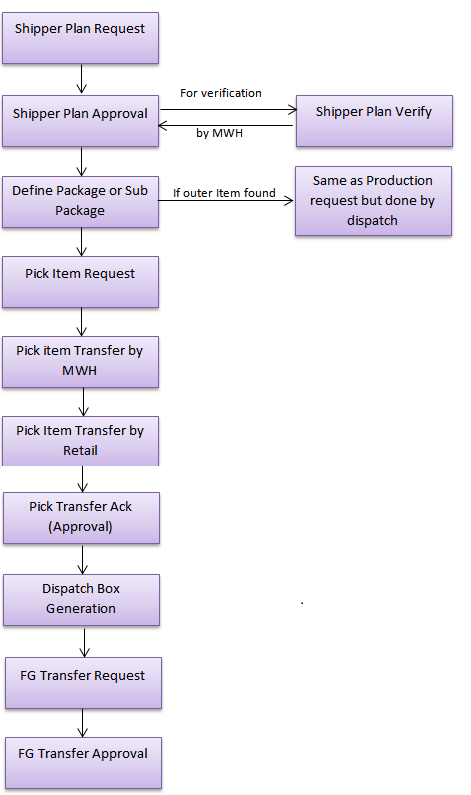

Production Process Flow

- Shipper Plan Request : user of glaze SCM will send a request to the manager of the warehouse for Items.

- Shipper Plan Approval : Manager of the Warehouse will send the request in the Mother Warehouse to verify the request ,if Mother Warehouse has the items as requested then warehouse manager will be notified that the request has been approved.

- Define Package Sub : Production area user will define packages and sub packages and if any item found which is outside the package then the same process will be followed as production request but it will be done by the dispatch user.

- Pick Item Request : Item pick request will be send to the Mother Warehouse.

- Pick Item Transfer By MWH : In this stage Mother Warehouse will transfer the boxes to the production area.

- Pick Item Transfer By Retail : In this Stage loose items will be transferred by the retail to the production area.

- Pick Transfer Ack(approval) : In this stage production user gives acknowledgement that he has received the item.

- Dispatch Box Generation: In this stage production area user will generate box for the items.

- FG Transfer Request: In this stage Boxes will move from production area to the dispatch area.

- FG Transfer Approval: In this stage dispatch user will give approval that Item has been received in dispatch area.

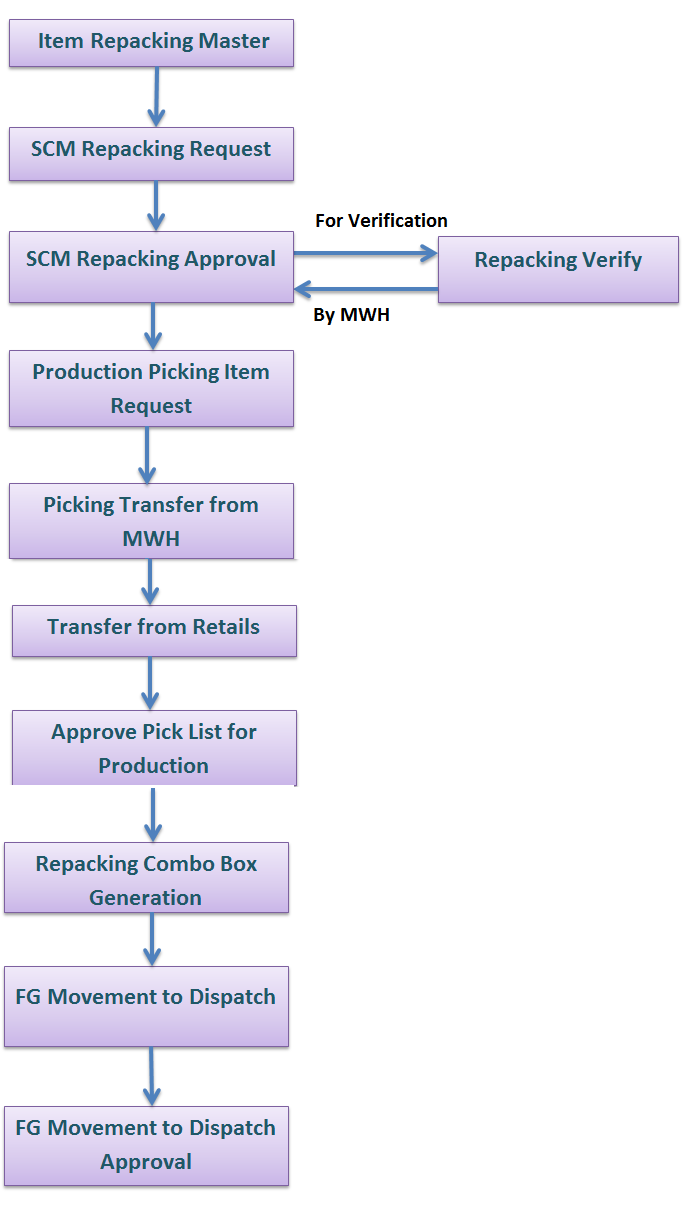

Repacking Process Flow

Description :Repacking is one of the important business activities during day to day warehouse operations. This article talks about warehouse management activities pertaining to major repacking scenarios; one in repacking is done either on materials from existing stock/inventory OR when material received from supplier.